Soon after the First World War broke out in August 1914, it became obvious that the British Expeditionary Force in France was ill prepared for the type of conflict that had developed. With both sides digging into trenches from the Channel coast to the Swiss border, the requirements were for types and quantities of artillery and ammunition that simply were not available to the BEF.

The War Office systems for weapons procurement were bureaucratic and out of date. Artillery production was limited to Royal Ordnance Factories and a few specialised firms, such as Vickers, and the production of shell cases and facilities for shell filling were similarly limited.

As the supply situation worsened during early 1915, David Lloyd George, the Chancellor of the Exchequer in Asquith's Government, pressed for radical changes in the supply lines which led to the creation of the Ministry of Munitions in May 1915, with Lloyd George as the Minister in charge. Even then the Whitehall battles continued, with the War Office resisting the changes proposed by Lloyd George. At one time, before the new Ministry had acquired the financial authority to purchase equipment, Lloyd George ordered a batch of mortars that were desperately needed, against the security of a financial guarantee by an Indian Maharajah, because the War Office system was so slow! However, by December 1915, all responsibility for procurement and development of military equipment had been passed to the Ministry of Munitions.

One of the key requirements for the BEF in France was for improved designs and improved numbers of Trench Mortars. The existing ROF design had a rifled barrel which required skilled craftsmen and specialised equipment for its manufacture; also these mortars had a low rate of firing and were not very accurate. An alternative design, developed by Wilfrid Stokes and rejected several times by the War Office, used cast tubes with no internal machining required with a simpler and quicker firing system, and it was more accurate. Against the opposition of the War Office, Trench Mortars based on the Stokes design became the weapon of choice. They did not need to be made in Royal Ordnance Factories because of their simpler design, as their manufacture could be contracted out to a wide range of engineering firms, and the supply line problems began to rapidly reduce. For example, in the second quarter of 1915, 121 trench mortars of all types were made but in the same quarter of 1916, 1976 were made (of which 1425 were Stokes mortars)

One problem that arose from the contracting out of manufacture was the need for proof testing of mortars before use. Accidents from faulty manufacture could prove fatal at the point of use. Existing ROF proof ranges, at Woolwich Arsenal and Shoeburyness (on the Essex coast) were insufficient and an additional proof test range was required. The search began for a new range.

It was against this background that the Frith Artillery Range was established, as described in Volume XI of "The Official History of the Ministry of Munitions":

"An important result of the manufacture of mortars by the trade was the organisation of a system of proof. So long as trench howitzers had been produced only by the Ordnance Factory and Vickers the only tests applied were departmental inspections in the one case and a firing test on the firm's own range in the other. in the autumn of 1915 it was decided to take Vickers' certificate of proof but to prove other trade-made mortars at Woolwich. In the spring of 1916, when mortars and ammunition were coming forward in unprecedented quantities, a distinct proof range was established for trench mortars at Buxton."

The same publication also has information on an additional role undertaken at the Frith Artillery Range from 1917:

"The breaking down of obsolete stores and the rectification of those rejected became a matter of importance during 1917 by reason of the general shortage of material. It was laid down ... that all rectification which involved explosive risks .... should generally be restricted to national factories. For this reason plant for rectifying trench mortars was installed at the Buxton store in July, 1917"

Information relating to this range can be found in a file at the National Archives at Kew (dealing with Ministry of Munitions papers, and the setting up the site) and in a file in the Chatsworth Archives (dealing with estate matters, the tenant farmers, restoration of the site etc). So far, no detailed information has been located on the types and numbers of weapons tested but it seems likely that a high proportion, if not all, of the Trench Mortars listed above were proof tested at The Frith range, making a major contribution to the efforts of the Army in France and elsewhere. As one example, the 3 inch Stokes mortar became the standard Trench Mortar in the winter of 1915 and in the second half of 1916, production of these mortars was between 100 and 200 per week.

The overall situation at the beginning of June 1916 is well summarised in the following account on the NA file:

"FRITH RANGE, BUXTON

The importance and rapid development of trench warfare initiated a conference at which D.G.M.D., D.T.W.S. and D.G.I.M. were represented, and the necessity of the immediate provision of a separate range for proving Trench Mortars and other trench warfare munitions was shown. The duty of finding and establishing a suitable range was charged to this department.

The S. of E. and the D.I.G.G. have approved the site, now known as the Frith Range, Buxton, which possesses many special advantages, and the negotiation for the land is being carried through by the Land Agent of the Northern Command under instructions of the Comptroller of Lands, War Office.

Plans have been prepared for laying out the site and for the erection of the buildings and works necessary to cover the requirements of the S. of E. and D.I.G.G., whose approval they have received.

With a view to acceleration and economy, Messrs. Pauling and Co. Ltd, Victoria Street, S. W. have been engaged, provisionally, as Construction Engineers on a commission basis of 2.5% on cost, plus extra allowances.. This firm is being employed on similar work under agreement by the Explosives Branch of the Ministry, who report the utmost satisfaction. Every effort is being made to advance this work sufficiently to allow a Military Camp to become established and commence firing in 14 days' time.

Enclosed are prints showing the site and plans of the buildings agreed upon, and a draft agreement, revised by the legal department, with Messrs. Pauling and Co. Ltd.

Certain movable equipment will be supplied by S. of E., and the necessary expenditure for works and plant, for which financial sanction is asked, has been estimated at £17,000. The works include Fencing; Railway connection, sidings and trollies; Levelling and Roadways; Mess Room, Barracks; Sheds and stables; Examination rooms, stores, magazines and danger buildings; Firing point works; Lighting, heating and water supply; Equipment and fittings, telephones."

The various sets of initials in this account stand for:

D.G.M.D., Director General of Munitions Design D.T.W.S., Director General Trench Warfare Supplies

D.G.I.M., Director General of Inspection of Munitions D.I.G.G., ?

S. of E. Superintendent of Experiments (this was a post based at Shoeburyness, see below)

"Dear Sir

I should be extremely grateful if you could help me in the following matter.

The War Office has asked me to identify any site which may exist in the Command area for the use of the Trench Warfare Department.

That Department is anxious to get land in the Midlands, North Midlands or South Yorkshire. The area required would be rectangular, two miles long by one mile wide. About one acre of this land would be required for buildings.

As much of the area as possible should be visible from the firing point from which it should preferably slope downwards. The soil should be dry.

There will be a good deal of heavy transport so it is desirable the site should be within four or five miles of a station and the nearer the better.

The matter appears to be of much urgency. It seems to me that possibly there are many waste tracts or tracts of land of little agricultural value in the North Midlands which would meet the requirements set out above. Moorland, heath etc on light soil might suit.

Land of this description is not always known of by the War Department and there is therefore a possible chance of you being able to help me in this matter, by suggesting any possible site so that we may more expeditiously meet the requirements of the Trench Warfare Department.

I should therefore be grateful if you could treat this as urgent and send me any particulars of any suitable site accompanying the same if possible by a plan.

yours sincerely C W Brighton,

Captain Northern Command Land Agent"

A follow up letter dated 26th June sets the position out:

"I am directed to inform you that certain land in the vicinity of the Frith has been definitely selected by the Ministry of Munitions for Trench Mortar Range.

Official notice signed by competent military authority has been served on each tenant and a separate plan has been served with that notice explaining in detail portions of their farm in respect of which total and exclusive possession is required."

The National Archives file covers the issues relating to the legal basis for setting up the range, the commissioning of a building contractor and the connections of the range to the railway and to electricity and water supplies. In each case, the urgency of the project is emphasised.

On the 6th May 1916, Lt Colonel Haynes, Superintendent of Experiments, Shoeburyness, circulated a rough draft of Bye Laws relating to the closure of the site. By the end of May, the draft had been through various stages of consultation and was ready to be sent to the printers with a target date of 1st July for the opening of the range. A short delay led to the Bye Laws coming into force on 1st August 2016 and notices were sent to the local newspapers and displayed as posters to announce that fact. The Bye Laws, made under the Defence of the Realm Act, 1914, prohibited any civilian from entering defined areas of land, with powers of arrest of any caught doing so, and some outer areas where sheep could be grazed at agreed times with the written permission of the Range Commander. A map was published showing these areas. The road from the Buxton to Leek road on Axe Edge to Glutton Bridge was closed at Dale Head on the western side and Harley Cross Gate on the eastern side. The range boundaries were described, in general terms, as:

" The Frith Artillery Range: The land between Harpurhill Works and Anthony Hill on the North, and the river Dove on the south, and between Thirkelow and Booth on the west, and the disused tramway and the road from Harley Cross Gate to the cross roads at Glutton Dale on the east."

At the same time, discussions were taking place on the appointment of a contractor for the construction of the site. A letter of 5th June 1916 recommends the firm of C Pauling and Co of Victoria Street London as the contractor and this was confirmed. The firm had good experience in this type of work and a good reputation for prompt action so, because of the urgency of the situation, the appointment was made very quickly

The contract was on a cost plus basis, with a profit margin of 2.5% for the contractor and Pauling's invoice sets out every item of expenditure down to door knobs and curtains. The following summaries were given for the residential buildings:

Officers Quarters 2419 Square Feet

Mess Room 1539 Square Feet

Barracks 2222 Square Feet

Latrines 399 Square Feet

In addition, stores, a firing shed, examination rooms and a magazine were constructed.

1162 yards of railway track were laid down, with one main track connected to the LNWR line and one siding. On site, about 300 yards of road were constructed for the quarters and about 500 yards for the operational area.

Originally, there was no road access to the site so that an access road 1342 yards long was constructed past the Ferney Bottom farm buildings. The present day road follows the same line, although with modern improvements.

There is no plan of the site layout on the file but there is a plan for the connection of the railway siding to the LNWR line which shows that this siding used the long straight disused section of the CHPR line, running approximately north/south. This same line is shown on the 6 inch to the mile Ordnance survey map, published 1923, together with two buildings fairly close to the LNWR route. These buildings probably correspond to the buildings constructed by Pauling for the range.

All of the land taken by the range was owned by the Duke of Devonshire and let out to tenant farmers who, obviously, experienced unsettling conditions.

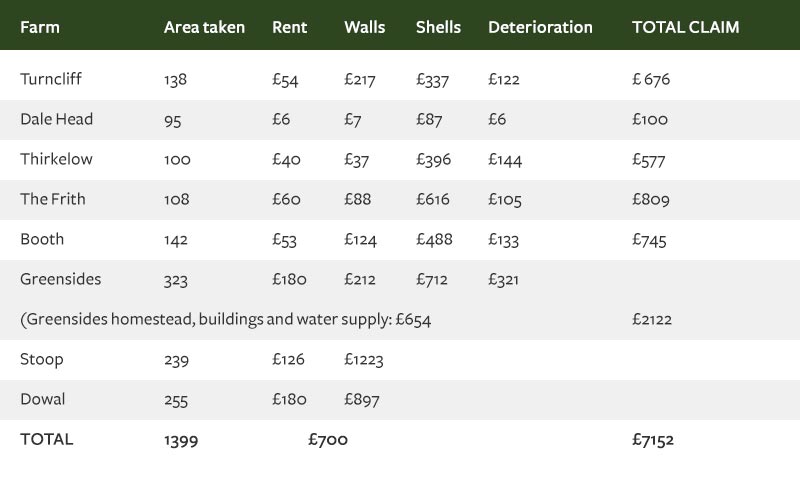

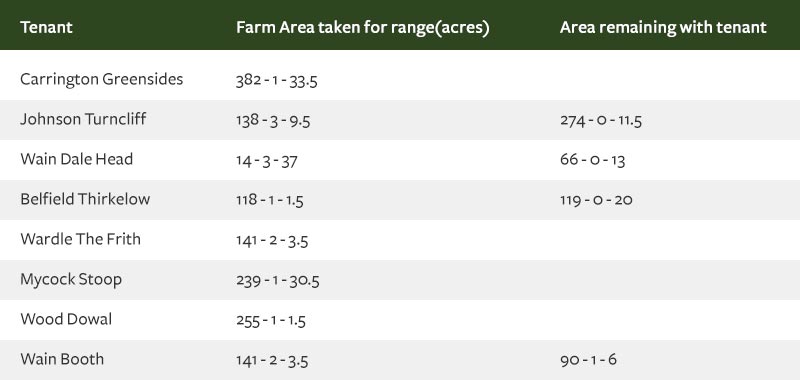

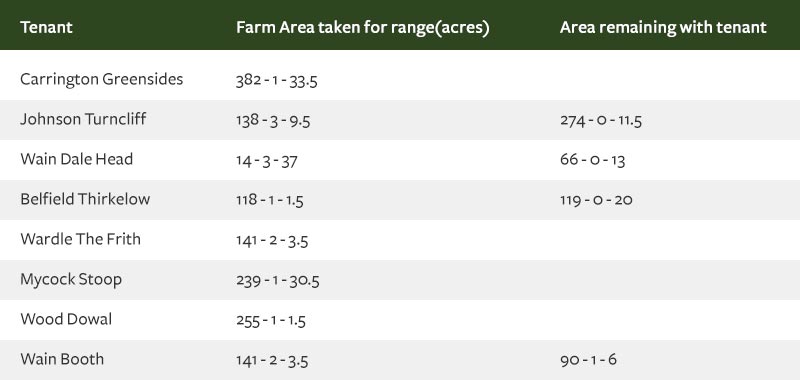

The land taken for the range was recorded as:

During the construction and fencing of the range, some problems arose with the tenants for the areas remaining with farmers. In one case, Drewry, the Duke's agent wrote that "fences are impossible as these are mountain sheep that can not be kept on restricted areas of land". In another case, there were protests because walls had been broken down and not repaired, leading to the loss of stock. In July 1916, Captain Brighton arranged an on site meeting with Drewry and the tenants and no further problems are recorded.

By the end of October 1916, construction work was almost finished and compensation arrangements were discussed. It was agreed that, from the 10th August 1916 (which seems to have been the actual takeover date), the tenants' rents would be reduced in proportion to the amount of land taken by the range and the Duke of Devonshire would be compensated by the Defence of the Realm Losses Commission.

Throughout the war, there was a steady improvement in the performance of trench mortars with regard to reliability, power and range. The Official History noted that the different types of mortars in use in 1915 had ranges from 340 to 900 yards. By 1917, some mortars had ranges up to 2000 yards. This increase in range required an extension of the range boundary at Greensides Farm(which was about 2000 yards from the firing point) and the vacating of the farm buildings. An unexpected consequence of this change was the interruption to the water supply to some local dairy farms. A reservoir had been constructed on Greensides Farm land which was supplied from a local spring, with the water pumped up by two ram pumps. Of the seven farms supplied from this reservoir, five were outside the range boundary. Although the reservoir and the pumps were protected by earth mounding, the shock waves from the exploding shells travelled through the ground and tripped out the pumps. Since the farm was now unoccupied and there was no civilian access to the site, the pumps remained out of action for long periods of time and the water supply to the farms failed. A letter from the Devonshire Estate Office in Buxton noted that this was interfering with important milk supplies to Manchester, Buxton and the Glutton Cheese Factory. After some delay, the problem was solved by the purchase of an oil fired pump to raise the spring water to the reservoir.

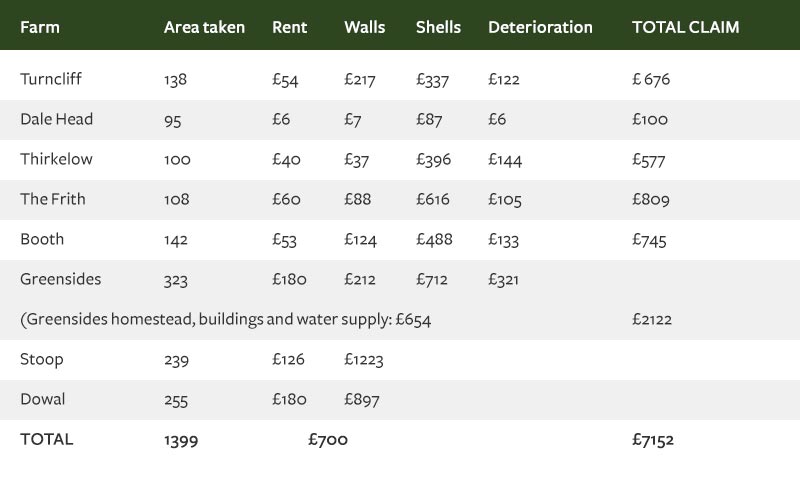

The range closed shortly after the end of the war in November 1918 and then attention turned to the restoration of the site and compensation for the losses incurred. One witness described the difficulty of walking across parts of the site and its resemblance to a battlefield. There were shell holes to be filled, shell fragments to be removed and repairs to be made to walls and buildings The terms of the takeover of the land meant that there was a two year period to claim for damage of that nature although there was an unlimited liability for the Army to remove any unexploded shells that might be discovered in later years. The damage claims were recorded under different headings as set out below:

Summary of areas taken by M of M, rent for that land and damage claim

So far, no detailed information on the number and type of trench mortars tested at the Frith has been located. One account states "as far as I am aware, all of the trench mortars manufactured and sent abroad were proof tested at the Frith".

The Official History records that in 1917, for example, about 6000 trench mortars were produced. Whatever the numbers the Frith Artillery Range clearly played a vital part in the equipping of the British forces on the western front.

Although the site is little known locally, some evidence of its activities remained. In the late 1970s, building work on the HSL site began to turn up significant quantities of shell fragments remained. These were cleared to allow the buildings to be completed but a follow up operation lasting several months removed over 30,000 shell fragments. As recently as February 2016, work on the preparation of the Peak Cycle Link Trail near Stake Side, turned up further fragments.